Information

2025-06-04 04:50

Application Development in PET Expandable Cable Wrap With Velcro for SB-SGS-15 1.5KV Silicone Resin Fiberglass TubingThe development of applications using PET expandable cable wraps with Velcro for SB-SGS-15 1.5KV silicone resin fiberglass tubing is a multifaceted endeavor that combines advanced material science, innovative design, and practical engineering solutions. Below is a detailed exploration of the key technologies involved and notable success stories that illustrate their effectiveness across various industries.

Key Technologies1. Material Science2. Expandable Design3. Velcro Fastening System4. Electrical Insulation5. Thermal Management6. Environmental Resistance1. Renewable Energy Sector2. Industrial Automation3. Telecommunications4. Aerospace Applications5. Automotive Industry Success Stories ConclusionThe application of PET expandable cable wraps with Velcro for SB-SGS-15 1.5KV silicone resin fiberglass tubing exemplifies the convergence of material science, engineering design, and practical application. By leveraging these advanced technologies, industries can enhance cable management, improve safety, and ensure the longevity of electrical systems across diverse environments. The success stories from various sectors underscore the versatility and effectiveness of this solution in addressing modern challenges in cable management and protection, paving the way for continued innovation and development in this field.

more...

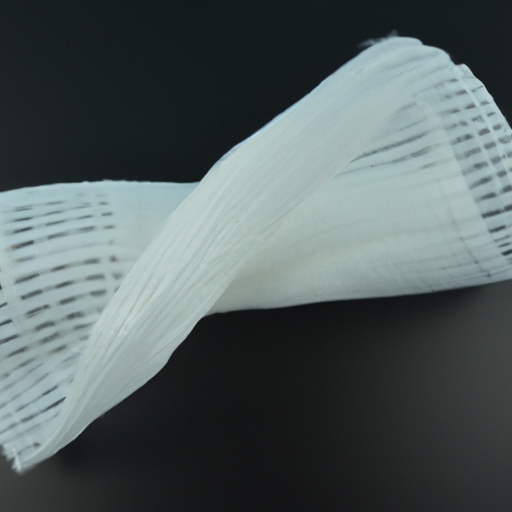

SBD-SWHF Single Wall Heat Shrink Tube: PET Woven Self-Closing Cable Wrap Overview

The SBD-SWHF Single Wall Heat Shrink Tube is an advanced cable management solution crafted from PET (Polyethylene Terephthalate) woven material. This self-closing cable wrap is engineered to provide robust protection and organization for cables across various industries, enhancing both functionality and aesthetics. Core Functional Technologies1. Self-Closing Mechanism2. Heat Shrink Properties3. Durability and Resistance4. Flexibility and Lightweight5. Thermal Management1. Automotive Industry2. Consumer Electronics3. Industrial Equipment4. Telecommunications5. Renewable Energy Application Development Cases Conclusion

The SBD-SWHF Single Wall Heat Shrink Tube, featuring PET woven self-closing cable wrap technology, presents a versatile and effective solution for cable management across diverse industries. Its combination of durability, flexibility, and ease of use positions it as a leading choice for protecting and organizing cables in a wide array of applications. As industries evolve and the demand for innovative cable management solutions increases, products like the SBD-SWHF wrap will continue to drive advancements in material technology and application development, ensuring optimal performance and reliability.

more...

2025-06-01 05:28

Application Development in Quartz Fiber Braided Sleeve for SB-PVC-HST: Key Technologies and Success StoriesDeveloping applications using Quartz Fiber Braided Sleeves for SB-PVC-HST (Silicone-Based Polyvinyl Chloride High-Temperature) involves several key technologies and methodologies. These materials are often used in industries requiring high-performance thermal insulation, electrical insulation, and mechanical protection. Below are some key technologies and success stories related to the application development of Quartz Fiber Braided Sleeves.

Key Technologies1. Material Composition2. Braiding Techniques3. Coating and Treatment4. Thermal Management5. Testing and Certification6. Customization1. Automotive Industry2. Aerospace Applications3. Industrial Machinery4. Renewable Energy5. Marine Applications Success Stories ConclusionThe application development of Quartz Fiber Braided Sleeves for SB-PVC-HST is a promising area with significant potential across various industries. By leveraging advanced materials, innovative manufacturing techniques, and rigorous testing, companies can create high-performance solutions that meet the demanding requirements of modern applications. The success stories highlight the versatility and effectiveness of these materials in enhancing product reliability and performance, paving the way for future innovations in high-temperature and high-stress environments.

more...

2025-05-30 03:38

Application Development in Double Layer Acrylic Fiberglass Sleeving for SB-PVC: Key Technologies and Success StoriesDouble Layer Acrylic Fiberglass Sleeving for SB-PVC (Styrene-Butadiene Polyvinyl Chloride) is a specialized material that has gained traction in various industries due to its unique properties and capabilities. This document outlines the key technologies involved in its development and highlights several success stories that demonstrate its effectiveness in real-world applications.

Key Technologies1. Material Composition and Properties2. Manufacturing Techniques3. Testing and Quality Assurance4. Customization and Design1. Automotive Industry2. Aerospace Applications3. Industrial Equipment4. Consumer Electronics5. Renewable Energy Success Stories ConclusionThe development of applications using Double Layer Acrylic Fiberglass Sleeving for SB-PVC exemplifies the synergy between advanced materials science and engineering. By leveraging key technologies in material composition, manufacturing, testing, and customization, industries can achieve significant improvements in performance, safety, and reliability. The success stories across various sectors underscore the versatility and effectiveness of this specialized sleeving in meeting the demands of modern applications, paving the way for continued innovation and growth in its use.

more...

SBS-SR-HST Double Layer Silicone Fiberglass Sleeving: Core Functional Technology and Application Development Core Functional Technology1. Material Composition:2. Temperature Resistance:3. Electrical Insulation:4. Flame Retardancy:5. Chemical Resistance:1. Automotive Industry:2. Aerospace Sector:3. Industrial Equipment:4. Renewable Energy:5. Marine Applications: Application Development Cases ConclusionSBS-SR-HST Double Layer Silicone Fiberglass Sleeving exemplifies a significant advancement in insulation technology, offering a unique blend of thermal stability, electrical insulation, and chemical resistance. Its successful application across various industries underscores its versatility and effectiveness in enhancing the performance and safety of electrical systems in challenging environments. As industries continue to evolve, the demand for such high-performance materials is expected to grow, paving the way for further innovations and applications in the future.

more...

SBS-SRT-FG PVDF Heat Shrink Tubing: Core Functional Technology and Application DevelopmentIntroduction to PVDF Heat Shrink Tubing

Polyvinylidene fluoride (PVDF) heat shrink tubing is a specialized polymer material known for its excellent chemical resistance, high-temperature stability, and mechanical strength. SBS-SRT-FG is a specific type of PVDF heat shrink tubing that is designed for various industrial applications, particularly in environments where durability and reliability are critical. Core Functional Technologies1. Heat Shrink Technology2. Chemical Resistance3. Electrical Insulation4. Flame Retardancy5. UV Resistance1. Aerospace Industry2. Automotive Sector3. Oil and Gas4. Medical Devices5. Telecommunications Application Development Cases ConclusionSBS-SRT-FG PVDF heat shrink tubing represents a versatile and effective solution for a wide range of applications across various industries. Its core functional technologies, including heat shrink capabilities, chemical resistance, electrical insulation, flame retardancy, and UV resistance, make it an ideal choice for demanding environments. As industries continue to evolve, the development and application of PVDF heat shrink tubing will play a crucial role in enhancing the performance and reliability of critical systems.

Future DirectionsAs technology advances, further research and development in PVDF heat shrink tubing could lead to enhanced properties, such as improved flexibility, lower production costs, and even greater environmental resistance. Innovations in manufacturing processes may also allow for the creation of custom sizes and shapes, catering to specific industry needs. The ongoing demand for high-performance materials in sectors like renewable energy, electric vehicles, and advanced telecommunications will likely drive the continued evolution of PVDF heat shrink tubing applications.

more...

2025-05-26 03:56

Application Development in Expandable Fiberglass Sleeving for SBS-SRT: Key Technologies and Success StoriesIntroduction to Expandable Fiberglass Sleeving

Expandable fiberglass sleeving is a highly adaptable protective solution utilized across multiple industries, particularly in applications that demand high-temperature resistance, electrical insulation, and mechanical protection. Its integration into Silicone-Based Systems for Rubber Technology (SBS-SRT) has become increasingly popular due to its unique attributes, including flexibility, durability, and resilience in harsh environments. Key Technologies1. Material Composition2. Manufacturing Techniques3. Thermal and Electrical Properties4. Customization and Versatility1. Automotive Industry2. Aerospace Sector3. Industrial Equipment4. Consumer Electronics Success Stories ConclusionThe application of expandable fiberglass sleeving in SBS-SRT exemplifies the convergence of advanced materials technology and practical engineering solutions. With its high-temperature resistance, electrical insulation properties, and adaptability, expandable fiberglass sleeving has proven to be an invaluable asset across various industries. The success stories underscore its effectiveness in enhancing product reliability, reducing maintenance costs, and improving overall performance, making it a preferred choice for manufacturers seeking to innovate and elevate their offerings. As industries continue to evolve, the role of expandable fiberglass sleeving will likely expand, driving further advancements in safety and efficiency.

more...

2025-05-25 03:50

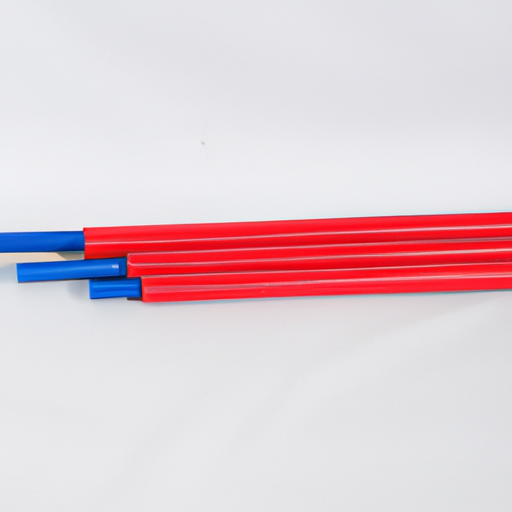

Overview of PFA TubesPFA (Perfluoroalkoxy) tubes are advanced fluoropolymer tubes recognized for their superior chemical resistance, thermal stability, and electrical insulation capabilities. These tubes are extensively utilized across various sectors, including electronics, chemical processing, and pharmaceuticals. The integration of PFA with materials such as silicone resin and fiberglass significantly boosts the mechanical strength and thermal performance of the tubes, making them ideal for rigorous applications.

Core Functional Technologies of PFA Tubes1. Chemical Resistance: PFA tubes are highly resistant to a broad spectrum of chemicals, including acids, bases, and solvents. This characteristic makes them particularly suitable for use in corrosive environments, ensuring longevity and reliability. 2. Thermal Stability: PFA can endure high temperatures (up to 260°C or 500°F) without compromising its integrity, making it appropriate for applications involving high-temperature processes.

3. Electrical Insulation: With excellent dielectric properties, PFA serves as an effective insulator for electrical applications. It is commonly employed in high-voltage environments, such as the SB-SGS-12 1.2KV silicone resin fiberglass tube.

4. Low Friction and Non-Stick Properties: The non-stick surface of PFA minimizes friction, making it ideal for applications where smooth material flow is essential.

5. Flexibility and Durability: PFA tubes are both flexible and durable, allowing for various configurations without the risk of cracking or breaking, which is crucial in dynamic environments.

Application Development Cases1. Electrical Insulation in High-Voltage Applications2. Chemical Processing3. Pharmaceutical Manufacturing4. Food and Beverage Industry5. Semiconductor Manufacturing ConclusionPFA tubes, especially when combined with silicone resin and fiberglass, provide a multitude of functional advantages that make them suitable for various high-performance applications. Their exceptional chemical resistance, thermal stability, and electrical insulation properties are essential in industries such as electronics, pharmaceuticals, and chemical processing. The development cases presented illustrate the effectiveness of PFA tubes in enhancing operational efficiency, safety, and product quality across diverse sectors, underscoring their value in modern industrial applications.

more...

2025-05-24 03:42

Application Development in FEP Heat Shrinkable Tube for SB-PFT Polyimide Film Tubing: Key Technologies and Success StoriesThe integration of FEP (Fluorinated Ethylene Propylene) heat shrinkable tubes with SB-PFT (Silicone-Based Polyimide Film Tubing) represents a significant advancement in material science, particularly for applications requiring high performance in extreme conditions. These materials are increasingly utilized across various industries, including aerospace, automotive, electronics, and medical devices, due to their superior properties. Below, we explore the key technologies that facilitate their application development and highlight notable success stories.

Key Technologies1. Material Properties and Selection2. Heat Shrink Technology3. Coating and Adhesion Technologies4. Manufacturing Techniques5. Testing and Quality Assurance1. Aerospace Applications2. Medical Devices3. Automotive Industry4. Consumer Electronics5. Telecommunications Success Stories ConclusionThe development of applications for FEP heat shrinkable tubes and SB-PFT polyimide film tubing is driven by advancements in material science, manufacturing technologies, and a comprehensive understanding of industry-specific requirements. The success stories across various sectors underscore the versatility and reliability of these materials, paving the way for innovative solutions in challenging environments. As technology continues to evolve, further advancements in these materials and their applications are anticipated, leading to even more successful implementations in the future. The ongoing research and development efforts will likely yield new applications, enhancing the performance and capabilities of FEP and polyimide-based solutions.

more...

SB-PET-HST: FEP Heat Shrink Tubing OverviewFEP (Fluorinated Ethylene Propylene) heat shrink tubing, particularly the SB-PET-HST variant, is a high-performance material that excels in demanding environments. Its unique properties make it a preferred choice across various industries, including medical, aerospace, electronics, food processing, and chemical manufacturing. Below, we delve into the core functional technologies, application development cases, and relevant articles that underscore the effectiveness of FEP tubing.

Core Functional Technologies of FEP Tubing1. Chemical Resistance 2. Thermal Stability 3. Low Friction Surface 4. Electrical Insulation 5. Non-stick Properties 1. Medical Devices 2. Aerospace and Automotive 3. Electronics 4. Food and Beverage 5. Chemical Processing 1. "Advancements in Fluoropolymer Technology" 2. "The Role of FEP Tubing in Medical Device Innovation" 3. "Thermal and Chemical Resistance of FEP Tubing" 4. "FEP Tubing in Aerospace Applications" 5. "Innovative Uses of FEP Tubing in Food Processing" Application Development Cases Articles and Research ConclusionFEP heat shrink tubing, such as SB-PET-HST, is a versatile and effective solution for a wide range of applications. Its core functional technologies—chemical resistance, thermal stability, electrical insulation, low friction, and non-stick properties—make it indispensable in industries like medical, aerospace, electronics, food processing, and chemical manufacturing. Ongoing research and development continue to expand its applications, solidifying its role as a critical material for engineers and manufacturers seeking reliable and high-performance solutions.

more...