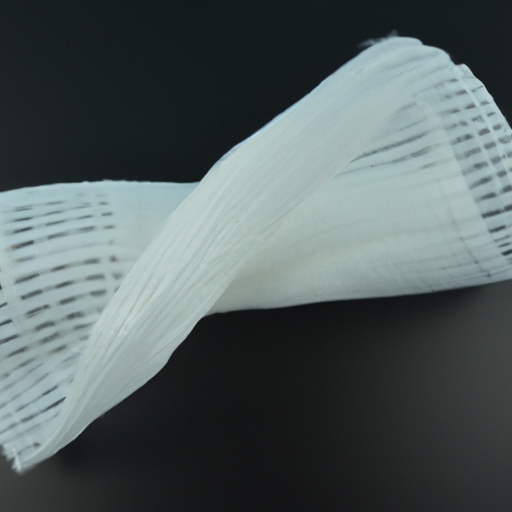

Application Development in Quartz Fiber Braided Sleeve for SB-PVC-HST: Key Technologies and Success Stories

Developing applications using Quartz Fiber Braided Sleeves for SB-PVC-HST (Silicone-Based Polyvinyl Chloride High-Temperature) involves several key technologies and methodologies. These materials are often used in industries requiring high-performance thermal insulation, electrical insulation, and mechanical protection. Below are some key technologies and success stories related to the application development of Quartz Fiber Braided Sleeves.

Key Technologies

| 1. Material Composition | |

| 2. Braiding Techniques | |

| 3. Coating and Treatment | |

| 4. Thermal Management | |

| 5. Testing and Certification | |

| 6. Customization | |

| 1. Automotive Industry | |

| 2. Aerospace Applications | |

| 3. Industrial Machinery | |

| 4. Renewable Energy | |

| 5. Marine Applications |

Success Stories

Conclusion

The application development of Quartz Fiber Braided Sleeves for SB-PVC-HST is a promising area with significant potential across various industries. By leveraging advanced materials, innovative manufacturing techniques, and rigorous testing, companies can create high-performance solutions that meet the demanding requirements of modern applications. The success stories highlight the versatility and effectiveness of these materials in enhancing product reliability and performance, paving the way for future innovations in high-temperature and high-stress environments.