SBD-PFA Heat Shrink Maker Sleeve: Core Functional Technology and Application Development

Introduction to Heat Shrink Maker Sleeves

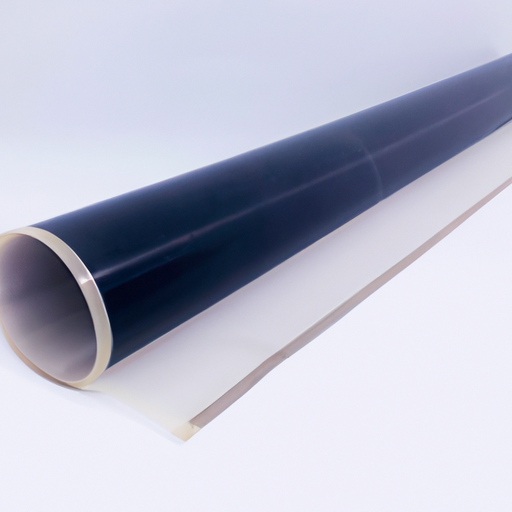

Heat shrink maker sleeves are specialized materials designed for insulation, protection, and identification of wires and cables across various industries. The SBD-PFA (Polyfluoroalkoxy) heat shrink maker sleeve stands out as a high-performance solution, offering unique properties that cater to demanding applications.

Core Functional Technology

| 1. Material Composition | |

| 2. Heat Shrink Technology | |

| 3. Customizability | |

| 4. Electrical Insulation | |

| 5. Flame Retardancy | |

| 6. Environmental Resistance | |

| 1. Aerospace Industry | |

| 2. Automotive Sector | |

| 3. Medical Devices | |

| 4. Telecommunications | |

| 5. Industrial Equipment |

Application Development Cases

Conclusion

The SBD-PFA heat shrink maker sleeve represents a significant advancement in materials technology, offering exceptional performance across various industries. Its unique properties, including high-temperature resistance, chemical stability, and customizability, make it an effective solution for a wide range of applications. As industries continue to evolve, the demand for reliable and high-performance insulation solutions like SBD-PFA sleeves will only increase, driving further innovation and application development. The versatility and reliability of SBD-PFA sleeves position them as a critical component in the future of electrical insulation and protection technologies.