Title: The Remarkable Thermal and Conductive Properties of Polyolefins: Preventing Pipe Shrinkage

Introduction (100 words) Polyolefins (PO) are a class of versatile polymers widely used in various industries due to their exceptional properties. In this article, we will explore the thermal and conductive properties of polyolefins, with a specific focus on how they prevent pipe shrinkage. Understanding these properties is crucial for engineers, manufacturers, and end-users to ensure the durability and reliability of pipes in different applications.

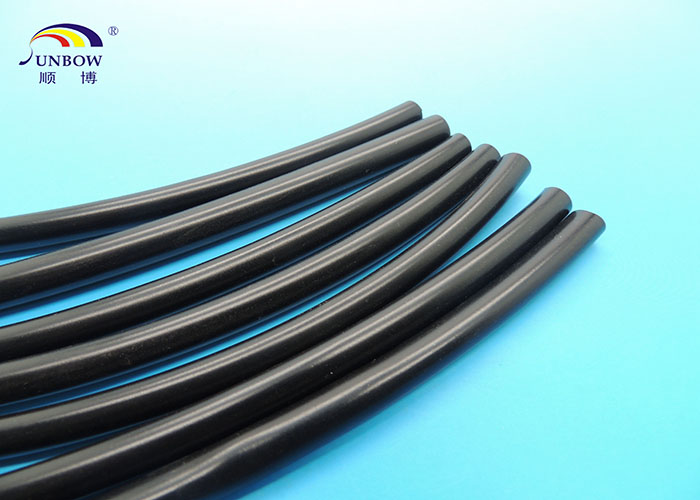

Thermal Conductivity of Polyolefins (300 words) Thermal conductivity refers to a material's ability to conduct heat. Polyolefins, including polyethylene (PE) and polypropylene (PP), exhibit low thermal conductivity, making them excellent insulators. This property is particularly advantageous in applications where heat transfer needs to be minimized, such as in plumbing systems, chemical processing, and HVAC installations.

The low thermal conductivity of polyolefins helps to maintain the temperature of fluids flowing through pipes, preventing heat loss or gain. This is especially important in industries where temperature control is critical, such as in the transportation of hot or cold liquids. By reducing heat transfer, polyolefins contribute to energy efficiency and cost savings.

Thermal Expansion and Pipe Shrinkage (400 words) Thermal expansion is the tendency of materials to expand or contract when exposed to temperature changes. When pipes are subjected to temperature variations, they expand or contract accordingly. However, if the expansion is not accommodated properly, it can lead to pipe shrinkage, causing leaks, cracks, or even pipe failure.

Polyolefins possess a unique property known as a low coefficient of thermal expansion (CTE). The CTE measures the change in size of a material with temperature variation. Due to their low CTE, polyolefins exhibit minimal expansion or contraction when exposed to temperature fluctuations. This property helps to prevent pipe shrinkage, ensuring the structural integrity and longevity of the piping system.

Moreover, polyolefins have a high resistance to thermal stress, which refers to the strain experienced by a material due to temperature changes. The combination of low CTE and high thermal stress resistance makes polyolefins an ideal choice for applications where pipes are exposed to extreme temperature variations, such as underground water distribution systems or industrial pipelines.

Conductive Properties of Polyolefins (300 words) Polyolefins are known for their excellent electrical insulation properties. They have high resistivity, meaning they do not conduct electricity easily. This characteristic is crucial in applications where electrical conductivity needs to be minimized, such as in cable insulation, electrical enclosures, and power transmission systems.

The non-conductive nature of polyolefins also plays a role in preventing pipe shrinkage. In situations where pipes are exposed to electrical currents or electromagnetic fields, the use of polyolefins as pipe materials helps to minimize the risk of electrical interference or damage. This is particularly important in industries such as telecommunications, where signal integrity is paramount.

Conclusion (100 words) Polyolefins, with their remarkable thermal and conductive properties, offer numerous advantages in preventing pipe shrinkage. Their low thermal conductivity, low coefficient of thermal expansion, and high resistance to thermal stress make them ideal materials for ensuring the durability and reliability of piping systems. Additionally, their non-conductive nature helps to minimize electrical interference and damage. As the demand for efficient and reliable pipe systems continues to grow, the utilization of polyolefins will undoubtedly play a significant role in meeting these requirements.