How to Choose Silicone Fiberglass Casing in Stock

Introduction

Silicone fiberglass casing is a versatile and essential material used across various industries, including automotive, aerospace, and electrical applications. Its unique properties, such as heat resistance, electrical insulation, and chemical resistance, make it a preferred choice for many applications. However, selecting the right silicone fiberglass casing can be a daunting task, given the myriad of options available in the market. This article aims to guide you through the process of choosing the right silicone fiberglass casing in stock, ensuring that you make informed decisions that meet your specific needs.

1. Understanding Silicone Fiberglass Casing

Definition and Composition

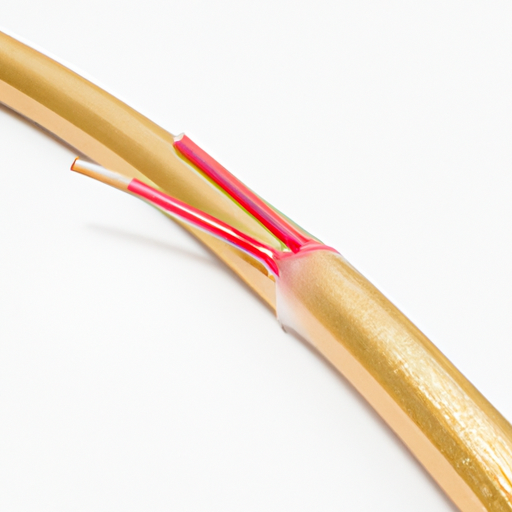

Silicone fiberglass casing is a composite material made from silicone rubber and fiberglass. The silicone provides excellent thermal stability and flexibility, while the fiberglass adds strength and durability. This combination results in a material that can withstand extreme temperatures and harsh environments.

Properties of Silicone Fiberglass Casing

Heat Resistance: Silicone fiberglass casing can typically withstand temperatures ranging from -60°C to 260°C (-76°F to 500°F), making it suitable for high-temperature applications.

Electrical Insulation: With excellent dielectric properties, silicone fiberglass casing is an effective insulator, making it ideal for electrical applications where safety and performance are critical.

Chemical Resistance: This material is resistant to a wide range of chemicals, including oils, solvents, and acids, which is crucial for applications in chemical processing and manufacturing.

Common Applications in Industries

Silicone fiberglass casing is widely used in various industries, including:

Automotive: For insulation and protection of wiring and components.

Aerospace: In applications requiring lightweight and heat-resistant materials.

Electrical: For insulating cables and components in high-voltage environments.

2. Key Factors to Consider When Choosing Silicone Fiberglass Casing

2.1. Temperature Resistance

When selecting silicone fiberglass casing, it is essential to consider the temperature ratings. Different applications have varying temperature requirements, and matching the casing to these requirements is crucial for performance and safety. Always check the manufacturer's specifications for temperature limits to ensure compatibility with your application.

2.2. Thickness and Size

The thickness and size of the casing are critical factors that influence its performance. To determine the appropriate thickness, consider the application’s mechanical stress and environmental conditions. Additionally, ensure that the size of the casing fits the components it will protect or insulate, as improper sizing can lead to inadequate protection.

2.3. Chemical Compatibility

Identifying the chemicals that the casing will be exposed to is vital for ensuring longevity and performance. Silicone fiberglass casing is resistant to many chemicals, but it is essential to verify compatibility with specific substances in your application. Consult chemical resistance charts provided by manufacturers to make informed decisions.

2.4. Electrical Properties

For electrical applications, the insulation ratings and dielectric strength of silicone fiberglass casing are paramount. Ensure that the casing meets the required electrical standards for your application, as inadequate insulation can lead to failures and safety hazards.

2.5. Flexibility and Durability

Evaluate the flexibility of the casing based on the specific application. Some applications may require more flexible materials to accommodate movement or bending, while others may prioritize durability in high-stress environments. Consider the operational conditions to choose the right balance between flexibility and durability.

3. Quality Standards and Certifications

When selecting silicone fiberglass casing, it is crucial to consider industry standards and certifications. Relevant standards, such as ASTM and UL, ensure that the product meets specific performance criteria. Certifications provide assurance of the product's reliability and safety. Always verify the quality of silicone fiberglass casing by checking for these certifications and reviewing the manufacturer's compliance with industry standards.

4. Sourcing Silicone Fiberglass Casing

4.1. Finding Reputable Suppliers

Identifying reliable manufacturers and distributors is essential for sourcing high-quality silicone fiberglass casing. Look for suppliers with a proven track record, positive customer reviews, and testimonials. Engaging with industry forums and networks can also help you find reputable sources.

4.2. Stock Availability

Understanding lead times and inventory management is crucial when sourcing silicone fiberglass casing. Before placing orders, check stock levels to ensure timely delivery. This is particularly important for projects with tight deadlines or specific timelines.

4.3. Cost Considerations

The price of silicone fiberglass casing can vary based on several factors, including material quality, thickness, and supplier. While it may be tempting to choose the lowest-cost option, balancing cost with quality and performance is essential. Investing in high-quality casing can lead to long-term savings by reducing the risk of failures and replacements.

5. Customization Options

Many suppliers offer customization options for silicone fiberglass casing, including variations in colors, sizes, and thicknesses. Custom solutions can be beneficial for specific applications that require unique specifications. When communicating your requirements to suppliers, be clear and detailed to ensure that the final product meets your needs.

6. Installation and Maintenance

Best Practices for Installing Silicone Fiberglass Casing

Proper installation is crucial for maximizing the performance of silicone fiberglass casing. Follow the manufacturer's guidelines for installation, ensuring that the casing is fitted correctly and securely. Use appropriate tools and techniques to avoid damaging the material during installation.

Maintenance Tips

To prolong the lifespan of silicone fiberglass casing, regular maintenance is essential. Inspect the casing periodically for signs of wear, damage, or chemical exposure. Clean the casing as needed, using appropriate cleaning agents that do not compromise its integrity.

Common Issues and Troubleshooting Advice

Be aware of common issues that may arise with silicone fiberglass casing, such as degradation due to extreme temperatures or chemical exposure. If problems occur, consult the manufacturer for troubleshooting advice and potential solutions.

7. Case Studies and Examples

Real-world applications of silicone fiberglass casing highlight the importance of proper selection. For instance, in the automotive industry, a manufacturer faced repeated failures in wiring insulation due to inadequate casing. After switching to a high-quality silicone fiberglass casing with appropriate temperature and chemical resistance, they significantly reduced failures and improved overall safety.

Another example can be found in the aerospace sector, where a company required lightweight, heat-resistant materials for engine components. By selecting the right silicone fiberglass casing, they achieved optimal performance and reliability, demonstrating the critical role of informed selection.

Conclusion

Choosing the right silicone fiberglass casing is essential for ensuring optimal performance and safety in various applications. By understanding the properties of silicone fiberglass casing and considering key factors such as temperature resistance, thickness, chemical compatibility, and electrical properties, you can make informed decisions. Additionally, sourcing from reputable suppliers and considering customization options can further enhance your selection process.

Conduct thorough research, consult experts, and prioritize quality to ensure that your silicone fiberglass casing meets the demands of your specific application. Making informed decisions will ultimately lead to improved performance and reliability in your projects.

References

- ASTM International. (n.d.). Standards for Silicone Fiberglass Casing.

- Underwriters Laboratories (UL). (n.d.). Certification Standards for Electrical Insulation.

- Manufacturer Technical Data Sheets for Silicone Fiberglass Casing.

- Industry Forums and Supplier Reviews for Sourcing Recommendations.