What are the Product Features of Self-Rolling Braided Sleeving?

Introduction

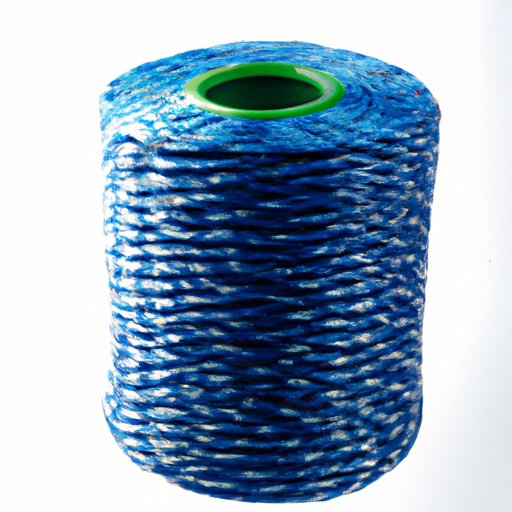

In the world of cable management and protection, braided sleeving has emerged as a popular solution for various industries. This versatile product is designed to encase and protect wires and cables from environmental hazards, abrasion, and wear. Among the different types of braided sleeving available, self-rolling braided sleeving stands out due to its unique design and functionality. Understanding the product features of self-rolling braided sleeving is essential for potential users looking to enhance their cable management systems. This blog post will delve into the definition, material composition, design features, functional benefits, customization options, applications, installation guidelines, and comparisons with traditional braided sleeving.

1. Definition and Purpose of Self-Rolling Braided Sleeving

Braided sleeving is a protective covering made from interwoven fibers that encase cables and wires. It serves multiple purposes, including protection from physical damage, insulation from electrical interference, and organization of cables to prevent tangling. Self-rolling braided sleeving takes this concept a step further by incorporating a mechanism that allows the sleeving to roll itself up when not in use. This innovative design not only enhances the aesthetic appeal of cable management systems but also provides practical benefits in terms of space-saving and ease of use.

The primary purposes of self-rolling braided sleeving include protecting sensitive cables in automotive, electronic, and industrial applications, as well as improving the overall organization of wiring systems. Its self-rolling feature makes it particularly advantageous in environments where space is limited or where cables need to be frequently accessed.

2. Material Composition

The effectiveness of self-rolling braided sleeving largely depends on the materials used in its construction. Commonly, these products are made from high-quality fibers such as polyester and nylon, which offer excellent durability and flexibility. Polyester is known for its resistance to UV rays and moisture, while nylon provides superior abrasion resistance.

In addition to the base fibers, self-rolling braided sleeving may also feature various coatings, such as silicone or PVC. These coatings enhance the sleeving's resistance to chemicals, heat, and environmental factors, making it suitable for a wide range of applications. The combination of these materials results in a product that is not only robust but also lightweight, ensuring that it does not add unnecessary bulk to the cables it protects.

3. Design Features

The design of self-rolling braided sleeving is a critical aspect of its functionality. The structure typically involves advanced braiding techniques that create a dense and flexible covering. Variations in thickness and density allow users to choose the right sleeving for their specific needs, whether they require a lightweight option for delicate electronics or a thicker variant for heavy-duty industrial applications.

The self-rolling mechanism is one of the standout features of this product. It works by utilizing a combination of elasticity and tension within the braided fibers, allowing the sleeving to retract when not in use. This feature not only keeps cables organized but also minimizes the risk of damage from accidental pulls or tugs.

4. Key Functional Features

Self-rolling braided sleeving offers a multitude of functional benefits that make it an attractive choice for various applications:

Protection Against Abrasion and Wear: The braided structure provides a robust barrier against physical damage, ensuring that cables remain intact even in harsh environments.

Resistance to Chemicals and Environmental Factors: The coatings and materials used in self-rolling braided sleeving enhance its resistance to chemicals, moisture, and UV exposure, making it suitable for outdoor and industrial use.

Thermal Insulation Properties: Many self-rolling braided sleeving options offer thermal insulation, protecting cables from extreme temperatures and preventing overheating.

Electrical Insulation Capabilities: The materials used in the sleeving provide excellent electrical insulation, reducing the risk of short circuits and electrical interference.

Lightweight and Space-Saving Advantages: The self-rolling feature allows for efficient storage and organization of cables, making it ideal for applications where space is at a premium.

5. Customization Options

One of the significant advantages of self-rolling braided sleeving is the availability of customization options. Users can choose from various sizes and diameters to ensure a perfect fit for their cables. Additionally, color options allow for aesthetic considerations, enabling users to match the sleeving with their branding or design preferences.

For businesses looking to promote their brand, custom printing and branding possibilities are also available. This feature allows companies to incorporate their logos or specific designs onto the sleeving, enhancing brand visibility while maintaining functionality.

Tailored solutions for specific applications are another aspect of customization. Manufacturers often work with clients to develop unique sleeving solutions that meet particular requirements, ensuring optimal performance in diverse environments.

6. Applications of Self-Rolling Braided Sleeving

Self-rolling braided sleeving finds applications across various industries, including:

Automotive Industries: In vehicles, self-rolling braided sleeving protects wiring harnesses from heat, abrasion, and environmental factors, ensuring reliable performance.

Electronics and Electrical Systems: The sleeving is widely used in consumer electronics, computers, and electrical systems to organize and protect sensitive wiring.

Industrial Machinery: In industrial settings, self-rolling braided sleeving safeguards cables from wear and tear, contributing to the longevity of machinery.

Other Sectors: The versatility of self-rolling braided sleeving extends to aerospace, marine, and telecommunications, where it provides essential protection and organization for critical systems.

7. Installation and Maintenance

Installing self-rolling braided sleeving is a straightforward process. Users should follow these guidelines for optimal results:

1. **Measure the Cables**: Determine the appropriate length and diameter of the sleeving needed for the cables.

2. **Cut the Sleeving**: Use sharp scissors or a cutting tool to cut the sleeving to the desired length.

3. **Slide the Sleeving Over the Cables**: Carefully slide the sleeving over the cables, ensuring a snug fit.

4. **Secure the Ends**: Use heat shrink tubing or cable ties to secure the ends of the sleeving, preventing it from slipping off.

To ensure optimal performance, users should regularly inspect the sleeving for signs of wear or damage. Cleaning the sleeving with a damp cloth can help maintain its appearance and functionality. Proper maintenance practices can significantly prolong the lifespan of self-rolling braided sleeving.

8. Comparison with Traditional Braided Sleeving

When comparing self-rolling braided sleeving to traditional options, several advantages become apparent. The self-rolling feature provides enhanced organization and space-saving benefits, making it ideal for environments where cables are frequently accessed. Additionally, the materials and construction techniques used in self-rolling sleeving often result in superior durability and flexibility.

However, there may be situations where traditional braided sleeving is preferred, particularly in applications where the self-rolling feature is not necessary. Cost considerations also play a role, as traditional sleeving may be more budget-friendly for users with less demanding requirements.

9. User Testimonials and Case Studies

Real-world examples of self-rolling braided sleeving in use highlight its effectiveness and benefits. For instance, an automotive manufacturer reported significant improvements in cable organization and protection after switching to self-rolling sleeving. Users in the electronics industry have praised the product for its ease of installation and ability to withstand harsh conditions.

Feedback from users across various sectors consistently emphasizes the advantages of self-rolling braided sleeving, including its durability, flexibility, and aesthetic appeal. Success stories showcase how this innovative product has transformed cable management systems, leading to increased efficiency and reduced maintenance costs.

10. Conclusion

In summary, self-rolling braided sleeving offers a range of features and benefits that make it an essential tool for cable management across various industries. Its unique design, material composition, and functional capabilities provide protection, organization, and aesthetic appeal. As technology continues to evolve, the importance of effective cable management solutions like self-rolling braided sleeving will only grow. For those seeking to enhance their cable management systems, considering self-rolling braided sleeving is a step toward improved efficiency and reliability.

References

- [Braided Sleeving: A Comprehensive Guide](#)

- [Material Properties of Braided Sleeving](#)

- [Applications of Braided Sleeving in Various Industries](#)

- [User Experiences with Self-Rolling Braided Sleeving](#)

This blog post provides a detailed overview of self-rolling braided sleeving, covering its features, applications, and advantages in various contexts. Each section is designed to inform and engage readers, encouraging them to consider this innovative product for their cable management needs.