Title: Exploring the Popular Models of Food Silicone Tubes

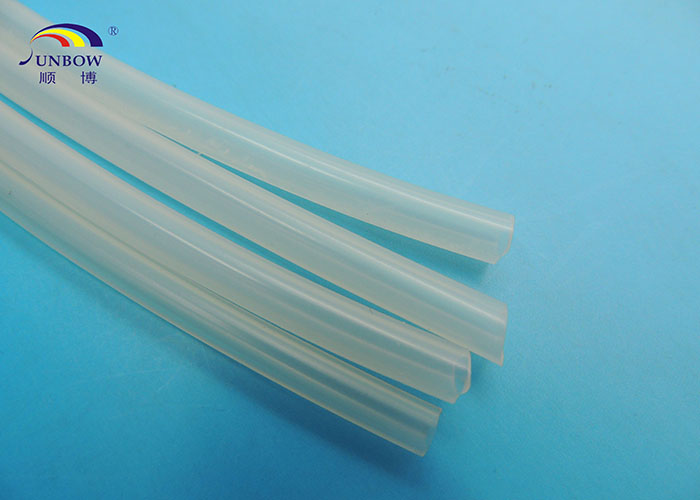

Introduction:Food silicone tubes have become an essential component in various industries, including food processing, beverage production, pharmaceuticals, and more. These tubes are known for their excellent flexibility, durability, and resistance to extreme temperatures, making them ideal for transporting liquids, gases, and semi-solid materials. In this article, we will delve into the popular models of food silicone tubes, highlighting their features, applications, and benefits.

1. Platinum-Cured Silicone Tubes: Platinum-cured silicone tubes are considered the gold standard in the food industry due to their exceptional purity and safety. These tubes are manufactured using platinum as a catalyst, resulting in a higher degree of cross-linking and a lower risk of leaching harmful substances into the food or beverage being transported. Platinum-cured silicone tubes are odorless, tasteless, and non-toxic, making them suitable for applications where maintaining the integrity and quality of the product is crucial.

Applications: These tubes are commonly used in food and beverage processing, dairy production, pharmaceuticals, and cosmetic industries. They are ideal for transferring sensitive liquids, such as juices, wines, sauces, and dairy products, without altering their taste or quality.

Benefits: - Excellent flexibility and kink resistance, allowing for easy installation and maneuverability. - High-temperature resistance, ensuring the tubes can withstand extreme heat during food processing or sterilization. - Non-reactive nature, preventing any chemical interactions between the tube and the transported material. - Easy to clean and sanitize, reducing the risk of contamination and ensuring compliance with food safety regulations.

2. Peroxide-Cured Silicone Tubes: Peroxide-cured silicone tubes are another popular choice for food-related applications. These tubes are manufactured using a peroxide catalyst, resulting in a slightly lower level of purity compared to platinum-cured silicone tubes. However, they still offer excellent performance and are more cost-effective, making them a preferred option for certain industries.

Applications: Peroxide-cured silicone tubes find applications in food and beverage processing, brewing, confectionery, and more. They are commonly used for transferring non-sensitive liquids, such as water, syrups, and non-alcoholic beverages.

Benefits: - Good flexibility and durability, ensuring long-lasting performance even under demanding conditions. - Wide temperature range, allowing for use in both hot and cold environments. - Cost-effective alternative to platinum-cured silicone tubes, making them suitable for budget-conscious applications. - Easy to sterilize and clean, reducing the risk of bacterial growth and contamination.

3. Reinforced Silicone Tubes: Reinforced silicone tubes are designed with an additional layer of reinforcement, typically made of polyester or fiberglass, to enhance their strength and pressure resistance. These tubes are ideal for applications that require higher pressure handling or where vacuum conditions are present.

Applications: Reinforced silicone tubes are commonly used in food processing, pharmaceuticals, chemical industries, and laboratory settings. They are suitable for transferring liquids, gases, and semi-solid materials under high-pressure conditions.

Benefits: - Enhanced strength and durability, allowing for use in demanding applications. - Excellent resistance to pressure, ensuring the tubes can withstand high-pressure environments without deformation or leakage. - Suitable for both suction and discharge applications, making them versatile for various industries. - Can be customized with different reinforcement layers to meet specific requirements.

Conclusion: Food silicone tubes are essential components in industries that require the safe and efficient transfer of liquids, gases, and semi-solid materials. The popular models discussed in this article, including platinum-cured silicone tubes, peroxide-cured silicone tubes, and reinforced silicone tubes, offer a range of features and benefits to cater to different applications. Whether it's ensuring the purity of food and beverages, withstanding high pressures, or maintaining flexibility and durability, these silicone tubes provide reliable solutions for various industries.