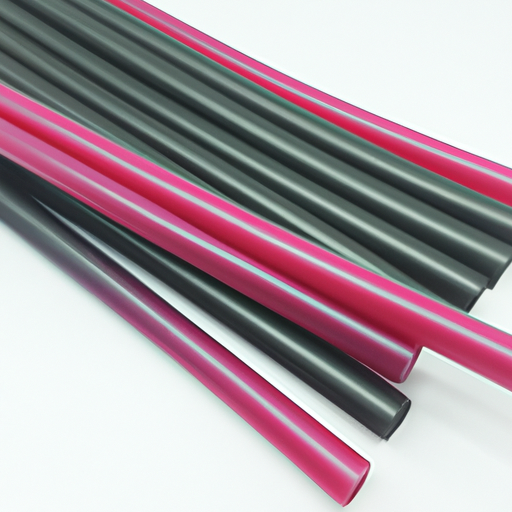

SBD-FEP FEP+PTFE Heat Shrinkable Tubing: Core Functional Technologies and Application Development Cases

FEP (Fluorinated Ethylene Propylene) and PTFE (Polytetrafluoroethylene) heat shrinkable tubing are advanced materials that offer a range of unique properties, making them indispensable in various industries. Below is a detailed overview of the core functional technologies and notable application development cases that highlight the effectiveness of FEP+PTFE heat shrinkable tubing.

Core Functional Technologies

| 1. Chemical Resistance | |

| 2. Temperature Resistance | |

| 3. Low Friction Coefficient | |

| 4. Electrical Insulation | |

| 5. Non-stick Properties | |

| 6. Shrinkage Ratio | |

| 1. Aerospace and Defense | |

| 2. Medical Devices | |

| 3. Automotive Industry | |

| 4. Telecommunications | |

| 5. Industrial Equipment | |

| 6. Food Processing |

Application Development Cases

Conclusion

FEP+PTFE heat shrinkable tubing represents a versatile and effective solution across multiple industries. Its unique properties—such as chemical resistance, temperature stability, and electrical insulation—make it an essential material for protecting and enhancing the performance of components in challenging environments. Ongoing research and development efforts continue to expand its applications, solidifying its role as a critical material in modern technology. As industries evolve, the demand for such advanced materials will likely grow, driving further innovation and application development.