Silicone heat shrink tubing is a type of tubing used for protecting and insulating wires and cables in high-temperature environments. These sleeves are made of silicone rubber, which is a new type of polymer material with good ductility and heat resistance. It has excellent physical reliability and can withstand multiple strict standards and disinfection and sterilization standards. It has excellent resilience and small permanent deformation (no more than 50% in two days at 200 ℃), resistance to reactive oxygen species, UV light, radiation sources, and other characteristics. Special silicone rubber also has wear resistance. They are typically used for various industrial and commercial applications, including aerospace, automotive, and military industries. (Glass fiber casing)

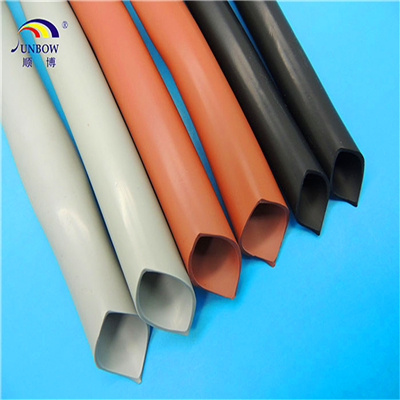

The SB-SR-HST model of our Shunbo silicone heat shrink tubing typically operates at temperatures ranging from -50 ° to 200 °, with a shrinkage temperature of 90 ° to 170 °. The approximate shrinkage ratio is 1.7:1

The structure of silicone heat shrink tubing is relatively simple. They are composed of thin and flexible silicone rubber layers, designed to wrap wires or cables that require insulation. Then, this layer of silicone rubber is exposed to high temperatures, causing it to shrink and form a tight protective seal around the wires or cables.

The process of making silicone heat shrink tubing is relatively simple. Firstly, the master batch secret recipe mixing → heated extrusion → sulfurized peroxide chemical crosslinking → heated expansion → packaging.

There are several advantages to using silicone heat shrink tubing. Firstly, they have high heat resistance and are very suitable for use in high-temperature environments. They are also very flexible and can adapt to various shapes and sizes. In addition, in terms of electrical performance, silicone heat shrink sleeves have a relatively small transformation when exposed to moisture or temperature rise. Even if a short circuit fault ignites, the converted silicon dioxide remains a conductor and insulator, ensuring that electrical equipment is working again. Therefore, they are most suitable for making cables, cables, and lead wires. (Glass fiber casing)

In the field of electronics, silicone heat shrink sleeves are commonly used to protect components such as connectors, sensors, components, and circuit boards. In the aerospace industry, they are typically used to protect electronic equipment and cables to ensure their normal operation in extreme high temperature environments. In the automotive industry, silicone heat shrink sleeves are commonly used to protect engine wiring harnesses and electrical components, in order to improve their high-temperature resistance and waterproof performance. In the industrial field, they are usually used to protect electronic equipment and cables.

Silicone heat shrink tubing can be used to protect aircraft engine wiring harnesses. Due to the extremely harsh environment surrounding the aircraft engine, including high temperatures and pressures, the engine wiring harness must have very high heat and corrosion resistance. Silicone heat shrink tubing can protect engine wiring harnesses in such extreme environments, improving their reliability and lifespan.

The advantages of silicone heat shrink tubing are not only high temperature resistance and flexibility. They also have excellent corrosion resistance and can resist harmful environments such as chemical corrosion, radiation, and ultraviolet radiation. In addition, the silicone heat shrink sleeve has excellent shrinkage at the joint, which can tightly fit wires and cables, improving electrical insulation performance and protective effect. Finally, silicone heat shrink tubing is easy to install and operate, which can greatly improve production efficiency.

In short, silicone heat shrink tubing is a high-performance protective material for wires and cables, with good high-temperature resistance, corrosion resistance, and protective performance. They are widely used in various industrial and commercial applications, which can improve the reliability and lifespan of electrical equipment.