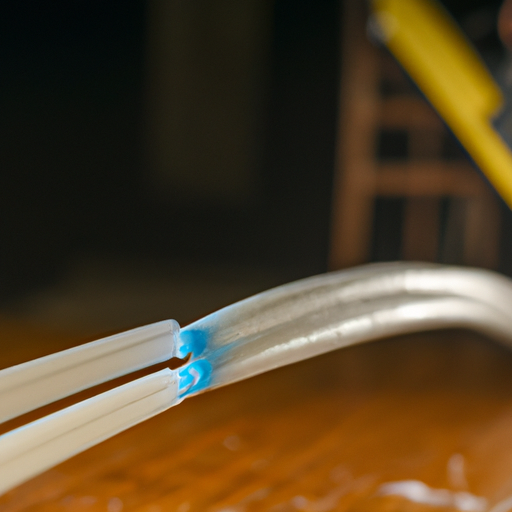

Application Development in Heavy Wall Heat Shrink Tube for SB-TGS-1050 Quartz Fiber Sleeving: Key Technologies and Success Stories

Developing applications for heavy wall heat shrink tubes, particularly for products like the SB-TGS-1050 quartz fiber sleeving, involves several key technologies and methodologies. Here’s an overview of the critical aspects and some success stories in this domain:

Key Technologies

| 1. Material Science | |

| 2. Manufacturing Processes | |

| 3. Testing and Quality Assurance | |

| 4. Application-Specific Design | |

| 5. Environmental Considerations | |

| 1. Aerospace Applications | |

| 2. Automotive Industry | |

| 3. Industrial Equipment | |

| 4. Telecommunications |

Success Stories

Conclusion

The development of heavy wall heat shrink tubes, particularly those incorporating quartz fiber like the SB-TGS-1050, showcases the intersection of advanced materials science, innovative manufacturing processes, and application-specific design. Success stories across various industries highlight the importance of these technologies in enhancing product reliability and performance in challenging environments. As industries continue to evolve, the demand for high-performance heat shrink solutions will likely drive further innovations in this field.

Future Directions

| Smart Materials: Integration of sensors within the heat shrink tubes to monitor temperature and stress in real-time.Smart Materials: Integration of sensors within the heat shrink tubes to monitor temperature and stress in real-time. |

| Advanced Coatings: Development of self-healing or anti-corrosive coatings to further enhance durability.Advanced Coatings: Development of self-healing or anti-corrosive coatings to further enhance durability. |

| Customization: Increased ability to customize shrink tubes for specific applications, including varying thicknesses and properties based on customer needs.Customization: Increased ability to customize shrink tubes for specific applications, including varying thicknesses and properties based on customer needs. |

These advancements will not only improve the performance of heat shrink tubes but also expand their applications across various industries, ensuring they meet the evolving demands of modern technology.