Application Development in Dual Wall Heat Shrink Tubing for SB-AGSD Double Layer Acrylic Fiberglass Sleeving: Key Technologies and Success Stories

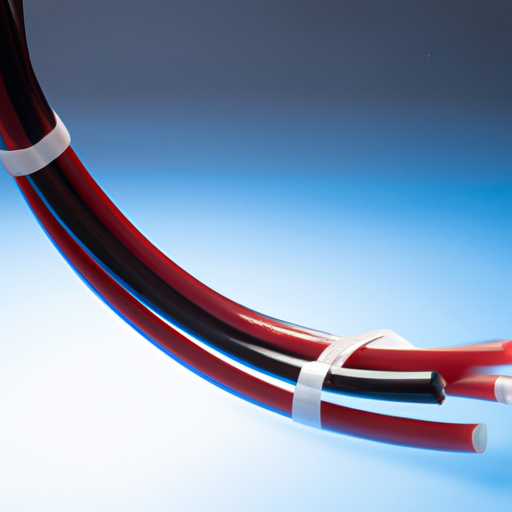

Dual wall heat shrink tubing, particularly in applications like SB-AGSD (Single Braided - Acrylic Glass Sleeving Double Layer), is pivotal in various industries, including electronics, automotive, aerospace, and telecommunications. This tubing integrates heat shrink technology with a dual-layer system, providing enhanced insulation, mechanical protection, and environmental resistance.

Key Technologies

| 1. Material Composition | |

| 2. Heat Shrinking Process | |

| 3. Dual Wall Design | |

| 4. Adhesive Layer | |

| 5. Customizable Properties | |

| 1. Aerospace Applications | |

| 2. Automotive Industry | |

| 3. Telecommunications | |

| 4. Consumer Electronics | |

| 5. Renewable Energy |

Success Stories

Conclusion

The application of dual wall heat shrink tubing, particularly in the context of SB-AGSD double layer acrylic fiberglass sleeving, exemplifies the intersection of advanced materials science and practical engineering solutions. The key technologies involved in its development have led to significant success stories across various industries, underscoring its importance in enhancing the durability, reliability, and performance of critical components. As technology continues to evolve, the potential for further innovations in this area remains promising, paving the way for even more robust and efficient applications in the future.