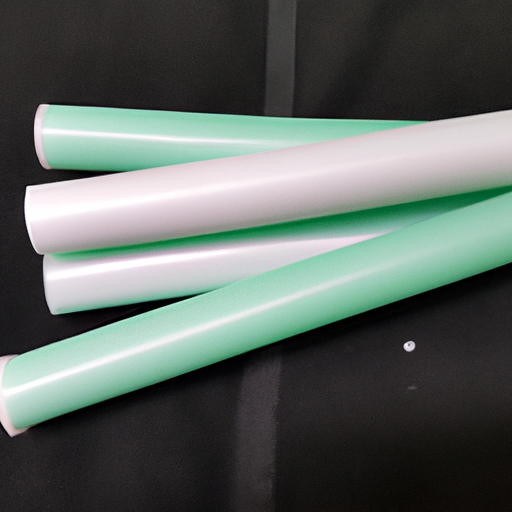

Application Development in Nonslip Heat Shrink Tube for SB-TGS-2S High Temperature-Resistance Special Fiberglass Sleeving

The development of applications utilizing nonslip heat shrink tubes, particularly the SB-TGS-2S high-temperature-resistant special fiberglass sleeving, is a multifaceted process that leverages advanced technologies and innovative practices. Below, we delve deeper into the key technologies and notable success stories that illustrate the effectiveness of this product in various industries.

Key Technologies

| 1. Material Science | |

| 2. Surface Treatment | |

| 3. Thermal Management | |

| 4. Custom Sizing and Shapes | |

| 5. Testing and Certification | |

| 1. Aerospace Industry | |

| 2. Automotive Applications | |

| 3. Industrial Equipment | |

| 4. Renewable Energy |

Success Stories

Conclusion

The development of applications using nonslip heat shrink tubes like the SB-TGS-2S is a testament to the intersection of advanced material science, innovative manufacturing techniques, and rigorous testing protocols. The success stories across various industries underscore the versatility and effectiveness of these products in enhancing the performance and reliability of critical components in high-temperature environments. As technology continues to advance, further innovations in materials and application techniques are anticipated, broadening the potential uses of high-temperature fiberglass sleeving and solidifying its role in modern engineering solutions.