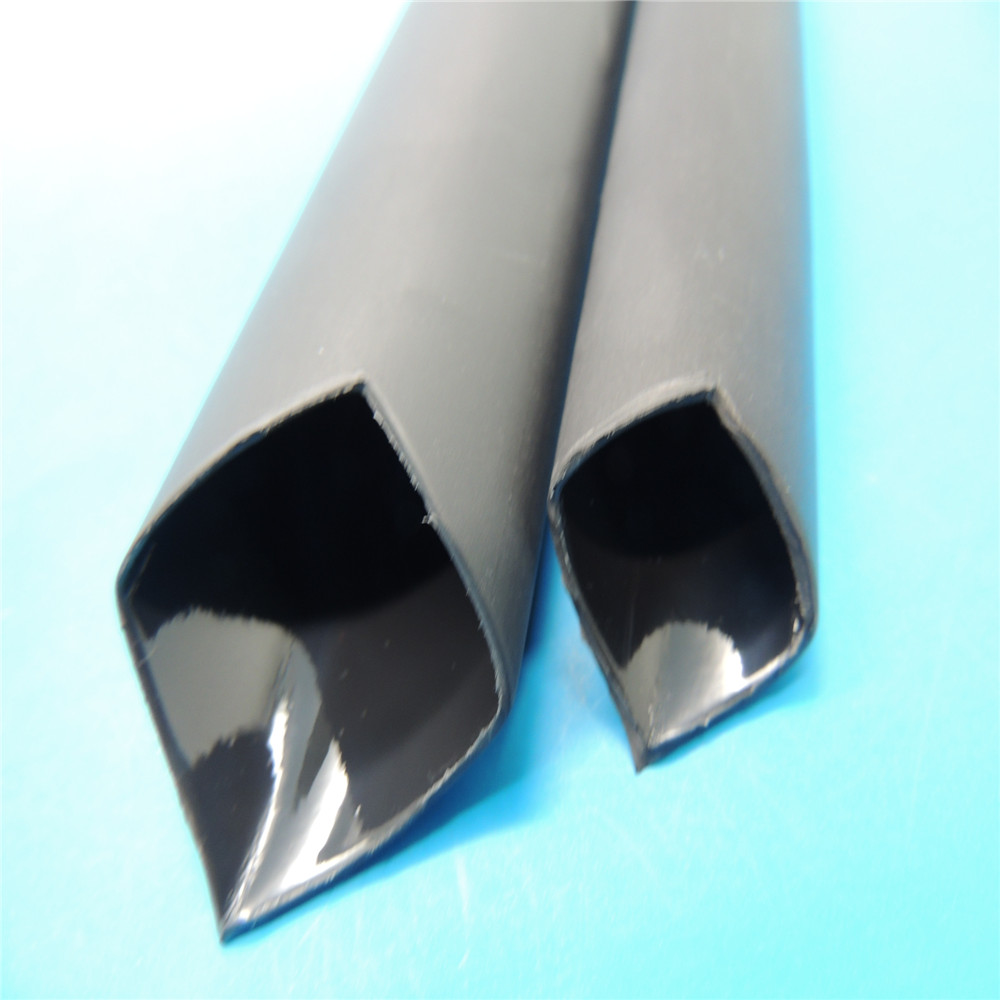

无卤阻燃热缩套管

型号: SBD-SWHF

工作温度: -55ºC ~ 125ºC

结构

无卤阻燃热缩套管采用高能电子束轰击交联的环保性聚烯烃热缩材料制造而成,属于环境友好型,燃烧时不产生毒气及有害物质,具有阻燃,绝缘,环保,柔软收缩快,性能稳定等诸多优点。通过600V/300V认证。

用途

应用领域:电子,通信,汽车,船舶,飞机制造等行。

产品特点

1.无卤, 无烟, 无毒, 阻燃, 柔软, 收缩快, 性能稳定

2.收缩比例: 2:1

3.收缩温度: 84ºC ~ 120ºC

表一 理气化电气性能

性能 | 单位 | 性能指标 | 测试方法/条件 | |

拉伸强度 | MPA | ≥10.4(老化前) | ASTM D 2671 | |

≥7.3(老化后) | 158ºC*168hrs | |||

断裂伸长率(%) | % | ≥200(老化前) | ASTM D 2671 | |

≥100(老化后) | 158ºC*168hrs | |||

耐热冲击 | - | 不发粘,不龟裂 | UL 224, 250ºC*4hrs | |

抗冷弯曲 | - | 不龟裂 | -30ºC*4hrs | |

击穿强度 | KV/mm | ≥15 | ASTM D 149 | |

耐电压 | 600V | - | UL 224 | 2500V, 60s 不击穿 |

300V | - | UL 224 | 1500V,60s 不击穿 | |

体积电阻率 | Ω. cm | ≥1×1014 | IEC 60093 | |

抗腐蚀性 | - | UL 224 | 158ºC*168h | |

铜安定性 | - | UL 224 | 158ºC*168h | |

阻燃性 | - | UL 224 | VW-1 | |

表二 规格

1) 无卤阻燃热缩管规格表(600V)

内径 | 收缩前尺寸 | 收缩后尺寸 | 标准包装 | 适用范围 | |

内径 | 内径 | 壁厚 | (米/盘) | ||

Φ0.6 | 0.9±0.2 | ≤0.40 | 0.33±0.10 | 200 | 0.4~0.7 |

Φ0.8 | 1.1±0.2 | ≤0.50 | 0.33±0.10 | 200 | 0.6~0.8 |

Φ1.0 | 1.5±0.2 | ≤0.65 | 0.36±0.10 | 200 | 0.75~0.9 |

Φ1.5 | 2.0±0.2 | ≤0.85 | 0.36±0.10 | 200 | 0.95~1.4 |

Φ2.0 | 2.5±0.2 | ≤1.00 | 0.45±0.10 | 200 | 1.1~1.8 |

Φ2.5 | 3.0±0.2 | ≤1.30 | 0.45±0.10 | 200 | 1.35~2.3 |

Φ3.0 | 3.5±0.2 | ≤1.50 | 0.45±0.10 | 200 | 1.6~2.7 |

Φ3.5 | 4.0±0.2 | ≤1.80 | 0.45±0.10 | 200 | 1.85~3.2 |

Φ4.0 | 4.5±0.2 | ≤2.00 | 0.45±0.10 | 200 | 2.1~3.6 |

Φ4.5 | 5.0±0.2 | ≤2.30 | 0.56±0.10 | 100 | 2.35~4.0 |

Φ5.0 | 5.5±0.2 | ≤2.50 | 0.56±0.10 | 100 | 2.6~4.5 |

Φ5.5 | 6.0±0.2 | ≤2.75 | 0.56±0.10 | 100 | 2.85~5.0 |

Φ6.0 | 6.5±0.2 | ≤3.00 | 0.56±0.10 | 100 | 3.1~5.4 |

Φ7.0 | 7.5±0.3 | ≤3.50 | 0.56±0.10 | 100 | 3.7~6.3 |

Φ8.0 | 8.5±0.3 | ≤4.00 | 0.56±0.10 | 100 | 4.2~7.2 |

Φ9.0 | 9.5±0.3 | ≤4.50 | 0.56±0.10 | 100 | 4.7~8.0 |

Φ10 | 10.5±0.3 | ≤5.00 | 0.56±0.10 | 100 | 5.2~9.0 |

Φ11 | 11.5±0.3 | ≤5.50 | 0.56±0.10 | 100 | 5.7~10 |

Φ12 | 12.5±0.3 | ≤6.00 | 0.56±0.10 | 100 | 6.2~11 |

Φ13 | 13.5±0.3 | ≤6.50 | 0.56±0.10 | 100 | 6.7~12 |

Φ14 | 14.5±0.3 | ≤7.00 | 0.70±0.10 | 100 | 7.3~13 |

Φ15 | 15.5±0.4 | ≤7.50 | 0.70±0.10 | 100 | 7.8~14 |

Φ16 | 16.5±0.4 | ≤8.00 | 0.70±0.10 | 100 | 8.3~15 |

Φ17 | 17.5±0.4 | ≤8.50 | 0.70±0.10 | 100 | 8.8~16 |

Φ18 | 19.0±0.5 | ≤9.00 | 0.70±0.10 | 100 | 9.3~17 |

Φ20 | 22.0±0.5 | ≤10.00 | 0.83±0.15 | 100 | 10.4~19 |

Φ22 | 24.0±0.5 | ≤11.00 | 0.83±0.15 | 100 | 11.4~21 |

Φ25 | 26.0±0.5 | ≤12.50 | 0.90±0.15 | 50 | 12.8~24 |

Φ28 | 29.0±0.5 | ≤14.00 | 0.90±0.15 | 50 | 14.4~29 |

Φ30 | 31.5±1.0 | ≤15.00 | 1.00±0.15 | 50 | 16~29 |

Φ35 | 36.5±1.0 | ≤17.50 | 1.00±0.15 | 50 | 18~34 |

Φ40 | 41.5±1.0 | ≤20.00 | 1.00±0.15 | 50 | 21~39 |

Φ45 | 46.5±1.0 | ≤22.5 | 1.00±0.15 | 25 | 23.5~44 |

Φ50 | ≥50 | ≤25.0 | 1.10±0.15 | 25 | 26~49 |

Φ60 | ≥60 | ≤30.0 | 1.20±0.15 | 25 | 35~55 |

Φ70 | ≥70 | ≤35.0 | 1.30±0.20 | 25 | 40~65 |

Φ80 | ≥80 | ≤40.0 | 1.30±0.20 | 25 | 45~75 |

Φ90 | ≥90 | ≤45.0 | 1.30±0.20 | 25 | 50~85 |

Φ100 | ≥100 | ≤50.0 | 1.30±0.20 | 25 | 55~95 |

Φ120 | ≥120 | ≤60.0 | 1.30±0.20 | 25 | 65~115 |

Φ150 | ≥150 | ≤75.0 | 1.30±0.20 | 25 | 80~145 |

Φ180 | ≥180 | ≤90.0 | 1.30±0.30 | 25 | 95~175 |

Φ210 | ≥210 | ≤105.0 | 1.30±0.30 | 25 | 110~205 |

Φ230 | ≥230 | ≤115.0 | 1.30±0.30 | 25 | 120~225 |

Φ250 | ≥250 | ≤125.0 | 1.30±0.30 | 25 | 130~240 |

2) 无卤阻燃超薄热缩管规格表(300V)

内径 | 收缩前尺寸 | 收缩后尺寸 | 标准包装 | 适用范围 | |

内径 | 内径 | 壁厚 | (米/盘) | ||

Φ0.6CB | 0.9±0.2 | ≤0.40 | 0.20±0.10 | 200 | 0.4~0.7 |

Φ0.8CB | 1.0±0.2 | ≤0.50 | 0.20±0.10 | 200 | 0.6~0.8 |

Φ1.0CB | 1.40±0.20 | ≤0.65 | 0.20±0.10 | 200 | 0.7~1.0 |

Φ1.5CB | 1.90±0.20 | ≤0.85 | 0.20±0.10 | 200 | 0.9~1.4 |

Φ2.0CB | 2.40±0.20 | ≤1.00 | 0.22±0.10 | 200 | 1.1~1.8 |

Φ2.5CB | 2.90±0.20 | ≤1.30 | 0.25±0.10 | 200 | 1.4~2.3 |

Φ3.0CB | 3.40±0.20 | ≤1.50 | 0.28±0.10 | 200 | 1.6~2.7 |

Φ3.5CB | 3.90±0.20 | ≤1.80 | 0.28±0.10 | 200 | 1.9~2.3 |

Φ4.0CB | 4.40±0.20 | ≤2.00 | 0.30±0.10 | 200 | 2.1~3.6 |

Φ4.5CB | 4.90±0.20 | ≤2.30 | 0.30±0.10 | 100 | 2.4~4.0 |

Φ5.0CB | 5.50±0.20 | ≤2.50 | 0.32±0.10 | 100 | 2.6~4.5 |

Φ6.0CB | 6.50±0.20 | ≤3.00 | 0.32±0.10 | 100 | 3.1~5.4 |

Φ7.0CB | 7.50±0.30 | ≤3.50 | 0.32±0.10 | 100 | 3.7~6.3 |

Φ8.0CB | 8.50±0.30 | ≤4.00 | 0.32±0.10 | 100 | 4.2~7.2 |

Φ9.0CB | 9.50±0.30 | ≤4.50 | 0.35±0.10 | 100 | 4.7~8.0 |

Φ10CB | 10.50±0.30 | ≤5.00 | 0.35±0.10 | 100 | 5.2~9.0 |

Φ11CB | 11.50±0.30 | ≤5.50 | 0.40±0.10 | 100 | 5.7~10.0 |

Φ12CB | 12.50±0.30 | ≤6.00 | 0.40±0.10 | 100 | 6.2~11.0 |

Φ13CB | 13.50±0.30 | ≤6.50 | 0.40±0.10 | 100 | 6.7~12.0 |

Φ14CB | 14.50±0.30 | ≤7.00 | 0.40±0.10 | 100 | 7.3~13.0 |

Φ15CB | 15.50±0.40 | ≤7.50 | 0.40±0.10 | 100 | 7.8~14.0 |

Φ16CB | 16.50±0.40 | ≤8.00 | 0.40±0.10 | 100 | 8.3~15.0 |

Φ17CB | 17.50±0.40 | ≤8.50 | 0.40±0.10 | 100 | 8.8~16.0 |

Φ18CB | 18.50±0.40 | ≤9.00 | 0.42±0.10 | 100 | 9.3~17.0 |

Φ20CB | 20.50±0.50 | ≤10.0 | 0.45±0.10 | 100 | 10.5~19.0 |

Φ22CB | 22.50±0.50 | ≤11.0 | 0.45±0.10 | 100 | 11.5~20.5 |

Φ25CB | 25.50±0.50 | ≤12.5 | 0.45±0.10 | 50 | 12.8~24 |

Φ28CB | 28.50±0.50 | ≤14.0 | 0.45±0.10 | 50 | 14.4~29 |

颜色: 标准色为黑色,其它颜色可订做。